Digital Inventories

Sponsored by Voxme Software, Inc.

Barriers To Adoption

Many service providers (asset-based movers that employ operational staff, operate trucks, warehouses and provide the physical moving and storage services) who are ready to adopt and implement digital inventories are rightfully concerned about choosing the right platform and software.

It’s not just the costs involved in licensing, setup and rollout efforts. In today’s world, more often than not, the job is done by subcontractors who can’t be trained on every single software company’s technology.

There’s also the issue of inventory control for which barcoding is the most common and effective method. Barcoding used to imply that a set of barcodes need to be transmitted from origin down to the bottom of the entire logistics chain, an idea that’s simply not realistic given the number of different stakeholders in a shipment’s supply chain.

For digital inventories to deliver true efficiency, the various service providers that interact with a shipment must be able to interchange information digitally once the information is available.

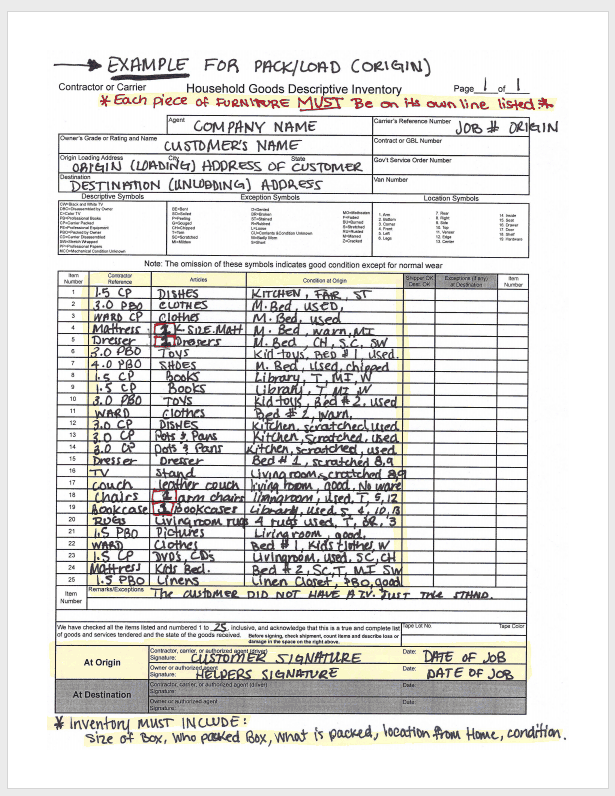

If the digital inventory system used to create the inventory and bar code labels at origin is unable to interchange data digitally to the warehouse providing Storage in Transit services, the digital inventory is printed onto a piece of paper. This brings us right back to the barely legible analog handwritten inventory of old.

Interoperability refers to the ability of different computer systems to exchange and make use of information. Without a solution to interoperability between the various computer systems, digital inventories will only produce a nice pdf file or printed document. It’s still valuable if it has sufficient information, but not very conducive to any kind of machine-based inventory control.

Innovative Solutions Arrive

Some software providers are recognizing these barriers to adoption and have brought innovative solutions to the market that deal effectively with the challenges. Moving service providers that are still coming to grips with automation can now implement lightweight applications that require little or no investment in new hardware and only minimum upfront commitment in terms of recurring and setup fees. Apps can be downloaded to existing smartphones and the user interfaces are designed for rapid familiarization and adoption.

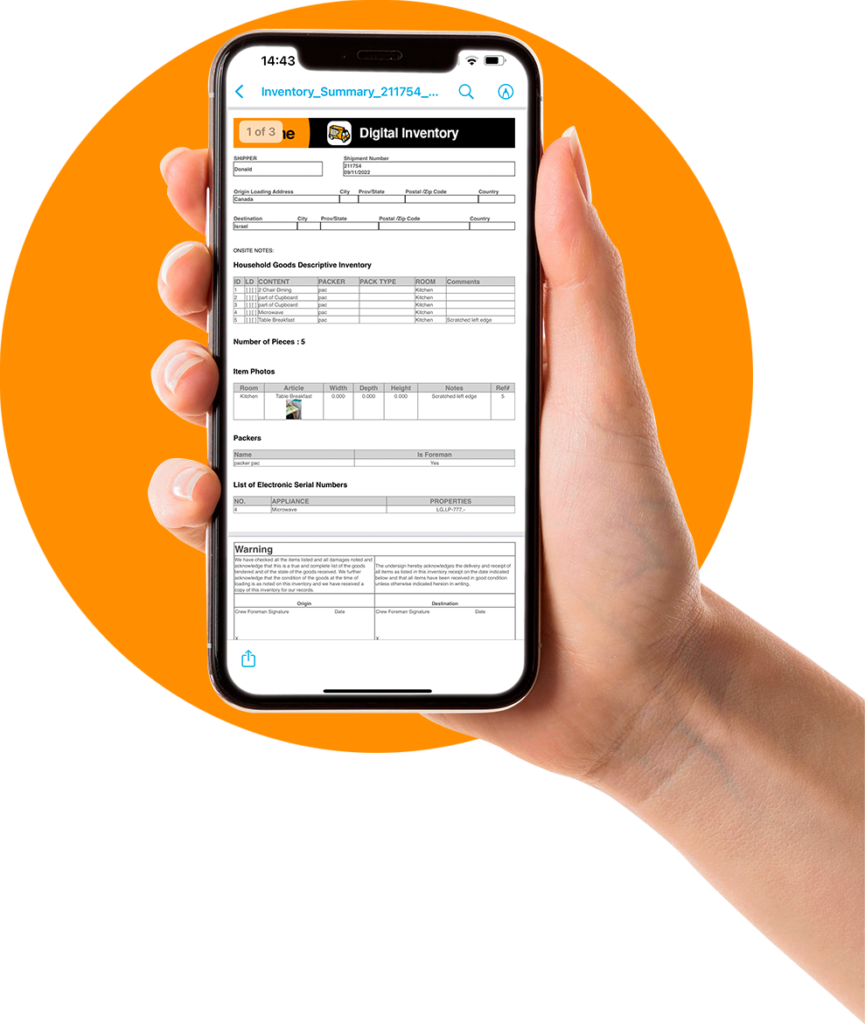

Some digital inventory system providers are now rolling out systems that bypass the need for interoperability altogether, at least in the inventory creation, check-off and chain of custody processes. This is achieved through the deployment of lightweight apps which can be instantly downloaded onto smart phones and tablets. A moving company can “push” a link to a van operator/subcontractor by text or email message. Clicking on the link downloads the lightweight app along with the individual shipment related information to the driver’s or crew leader’s smart phone or tablet.

While the app is lightweight, it is full featured permitting the driver/crew leader to efficiently create a digital inventory. When the inventory is complete, the crew leader can either pass the smart phone to the customer to review and sign or share the inventory pdf with the customer instantly to complete the review and sign off. The crew leader finishes the job by pushing the completed, signed inventory back to the moving company.

At the next warehouse, be it still at origin or destination, if Storage in Transit is required; the moving company can push a link to the warehouse which allows them to download a Checkoff App, sometimes called a “bingo sheet”, to complete the process. At time of final delivery to the customer’s residence, the link can be sent to the delivery crew leader or the transferee who can download the app, and origin inventory to complete the delivery checkoff process at residence. The checkoff summary document (pdf) containing photos of damaged articles and unmarked packages along with signatures can be shared immediately with all the key stakeholders in the relocation.

Feedback from initial trials is positive and point to ready acceptance by service providers and van operators.

What Becomes Possible?

The widespread adoption of digital inventories creates the potential for some interesting possibilities:

General Availability – Digital inventory systems became easy to use and affordable to adopt by movers of any size, starting from the owners/ operators. Moreover, the pervasive use of smartphones removed the need for any additional hardware investments and prepared the target digital inventory users for learning yet another app. Coupled with quickly disappearing handwriting and spelling skills, it bodes well for quick and large scale acceptance of the digital inventory apps.

Customer Satisfaction – One of the single biggest causes of customer dissatisfaction relates to customer misunderstanding of the inventory process and its importance in establishing a piece count, condition report at origin and acceptance report at destination. Digital inventories will make the process clear, transparent and will demystify the exception coding system.

Claims Reduction – Yes, as with any change, there is a process of becoming familiar with the system but once this investment has been made the returns are exceptional in the form of efficiency and job satisfaction..

Digital Translation – The ISO 17451 Standards, which the IAM helped to develop, has language translation capability built in. The description “Sofa” becomes encoded into a unique number as does the exception “Scratched” Once encoded, translation becomes simple. This not only makes translations for customs clearance more efficient, offering the inventory in the native language of operations crews at destination makes the inventory reconciliation process more accurate and efficient.

Utilizing barcodes. – Bar codes can be utilized at every step of the inventory checking process. Itemized barcodes are an integral part of a digital inventory system facilitating accurate accountability at every step of the chain of shipment custody. Barcodes also increase operational efficiency reducing the time required to prepare and check off inventory items.

Inventory Checkoff App – Utilizing cloud-based technology, software providers are starting to offer a lightweight application that can be downloaded to a user’s device along with the data specific to a shipment’s inventory. This allows the customer, driver or service provider to use their own device to access and check off the inventory simply by clicking a link in an e-mail or text message.

Data Interchange -The ISO 17451 Standards provide the road map for digital data interchange of inventory information. Origin agents will be able to upload the information seamlessly to not only the destination agent but also the Transportation Service Provider, Claims Adjudicator or Insurance Company (if required), and important to the customer.

Data interchange will also pave the way for digital clearance of international shipments which will inevitably become a requirement by certain countries. It is important for the industry to establish and offer a standard before the customs departments of countries stipulate their own standards.

Wider Data Interchange – The standards and infrastructure necessary for the efficient interchange of inventory data becomes a foundation upon which the moving industry can build standards for the interchange of comprehensive shipment data. This holds the potential for some of the largest efficiency and quality improvement gains for our industry and the related mobility services industry that we are a part of.

About Voxme Software, Inc.

Voxme Software was founded in 2003 with a vision to help facilitate efficiency and connectivity within the moving industry the application of leading-edge technology. Thanks to the rapid development of smart devices and cloud technology, Voxme has enjoyed industry wide adoption of its pre-move survey (Voxme Estimator) and driver inventory (Voxme Inventory) app, which are used by the largest military and residential movers in the world.

True to the company mission of making digital inventory accessible to any mover anywhere in the world, Voxme has rolled out a simple digital inventory and bingo label portal that provides the 3 cornerstones of a real inventory control (click on the links to view the videos):

This allows moving professionals to build a simple solution that suits their needs and pay as you go on a transaction-based pricing model.

“We started using electronic inventories back in 2015 and we’ve been steadily increasing our usage. We are just shy of about 27,000 inventories right now. All of our implementations are done overseas. We don’t have any CONUS (continental US) agents. We had few different challenges – languages and learnings and things like that but it’s been going very well for us.” – Ken Nishida – The Pasha Group

4 Comments

Sandra Clary · September 13, 2021 at 3:56 pm

Thank you for bringing attention to this important topic! Digital inventories (aka electronic inventories) are an essential part of a mover’s toolkit — for legibility and for compliance with client and customer requirements. *This functionality is included for all of our EDC-MoveStar® Mobile customers, including all of our EasyDPS® customers who are facing the proposed mandate from USTRANSCOM.* Digital inventories also give the ability for better shared user/contributor features and electronic signatures for customers and contributors. Great topic!

Ray Dasilva · September 13, 2021 at 9:07 pm

The ISO 17451-1 and ISO 17451-2 documents are available for purchase at the ISO website. IAM Members that have Validated their compliance to the standards can get interim updates made to the code in between republication of the code every 4 or 5 years.

Chuck White · September 14, 2021 at 12:42 pm

No question that in the U.S. Department of Defense world the requirement to use digital inventories is on the horizon. The recently proposed DOD rules for 2022 indicate that digital inventories will be a DOD requirement starting April 1, 2022. Will that requirement come to fruition by that date? At this point it is unclear but this is unquestionably on DOD’s radar and will eventually be a requirement. Probably sooner rather than later. DOD moves between 350,000 and 400,000 shipments per year. That obviously is going to have an impact on the entire moving market.

IAM will be taking the lead to try to inform and educate the market place on how and where one can fulfill this requirement. Stay tuned!

Max Kreynin · September 15, 2021 at 5:23 pm

Thank you, Ray and Chuck, for helping educate IAM members and, realistically, the entire moving industry on the importance of the digital inventory. It goes well beyond the military moves. The key message is that the real down to earth technology is available here and now. The point is to keep things simple and go step by step. Once the industry embraces the electronic way, it will discover all the benefits that come with it.